When I recently accompanied my wife to the grocery discounter near us, I discovered inexpensive cylindrical decorative glasses, approx. 120 mm in diameter and 200 mm high, on the display table. That would be half the battle for a wood turning project that I've had saved in my to-do app for a while! Grinning, I add this item to our shopping cart. My wife looks at me questioningly, but actually she knows I hate always to talk about "unlaid eggs."

When I recently accompanied my wife to the grocery discounter near us, I discovered inexpensive cylindrical decorative glasses, approx. 120 mm in diameter and 200 mm high, on the display table. That would be half the battle for a wood turning project that I've had saved in my to-do app for a while! Grinning, I add this item to our shopping cart. My wife looks at me questioningly, but actually she knows I hate always to talk about "unlaid eggs."

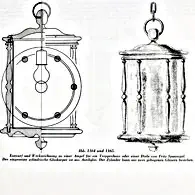

Back home, I scim through Fritz Spannagel's DRECHSLERWERK. I quickly found the page with the design of a hallway lamp that I had in mind. But for a brief moment I doubt whether the - somewhat outdated - design represents the right basis for my project. In my opinion, a functional ceiling light should also be able to emit its light directly downwards. After all, we want everyone to see straight away that you could definitely eat from the floor here! So instead of the base plate I will turn just a ring. So the appears more modern and the whole room locks brighter.

Back home, I scim through Fritz Spannagel's DRECHSLERWERK. I quickly found the page with the design of a hallway lamp that I had in mind. But for a brief moment I doubt whether the - somewhat outdated - design represents the right basis for my project. In my opinion, a functional ceiling light should also be able to emit its light directly downwards. After all, we want everyone to see straight away that you could definitely eat from the floor here! So instead of the base plate I will turn just a ring. So the appears more modern and the whole room locks brighter.

The incandescent lamps of earlier times only lasted a few hours of operation. The order in which the lamp was dismantled with which special tools to access the lamp could easily be stored in the short-term memory, even with the most complex constructions, until the next bulb replacement. However, modern LED lamps last longer than an average long-term memory. That's why lights today have to be designed in such a way that bulb replacement can be done without tools and in a self-explanatory manner. In my case, in order to achieve this goal, the glass floor is still in the way. The solution: The glass base has a 42mm hole for the socket. A job that required a lot of patience from me, because the glass base is approx. 12 mm thick in the middle. In contrast, turning the parts made of pear wood was almost child's play.

The incandescent lamps of earlier times only lasted a few hours of operation. The order in which the lamp was dismantled with which special tools to access the lamp could easily be stored in the short-term memory, even with the most complex constructions, until the next bulb replacement. However, modern LED lamps last longer than an average long-term memory. That's why lights today have to be designed in such a way that bulb replacement can be done without tools and in a self-explanatory manner. In my case, in order to achieve this goal, the glass floor is still in the way. The solution: The glass base has a 42mm hole for the socket. A job that required a lot of patience from me, because the glass base is approx. 12 mm thick in the middle. In contrast, turning the parts made of pear wood was almost child's play.